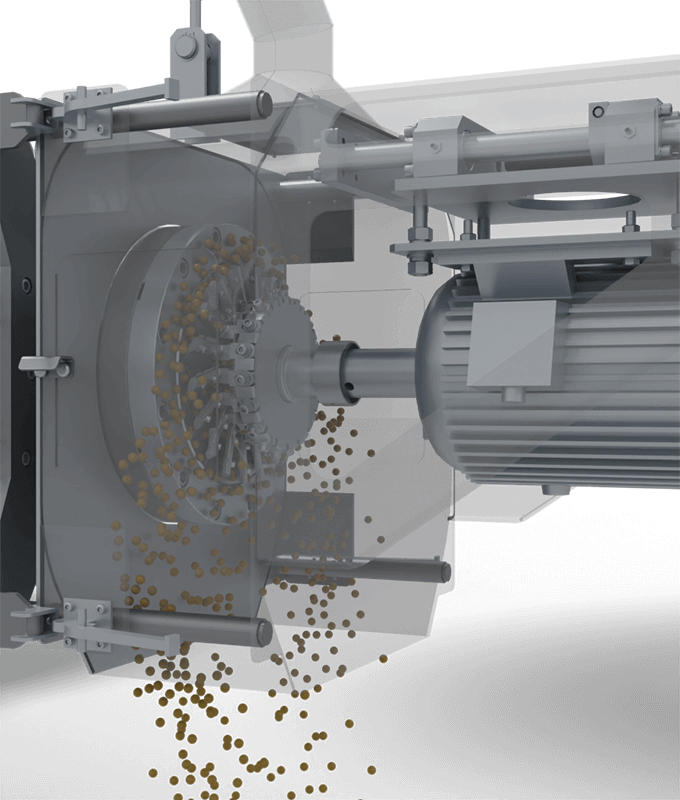

In the realm of aquaculture, the quality of feed is critical for the health and growth of aquatic species. The FAMSUN Twin-Screw Aqua Extruder stands out for its ability to produce uniform pellets with a high degree of gelatinization. This advanced food extruder is designed to optimize production efficiency while ensuring the strict standards in pellet quality.

Advanced Conditioning Technology

FAMSUN employs innovative conditioning technology that plays a crucial role in achieving uniformity in extruded pellets. By carefully controlling temperature and moisture levels, the Twin-Screw Aqua Extruder ensures that every pellet has the same characteristics, leading to enhanced feed performance. This precision in conditioning is essential for maximizing the nutritional value of aquafeeds.

Optimized Screw Configuration

The screw configuration techniques used in the FAMSUN Twin-Screw Aqua Extruder are designed for optimal performance. Through advanced Computational Fluid Dynamics (CFD) simulations, the discharge device and die hole distribution are meticulously optimized. This results in an impressive expansion coefficient variance of ≤0.1, ensuring that each pellet meets the highest quality standards.

High Gelatinization Degree

One of the standout features of the FAMSUN Twin-Screw Aqua Extruder is its ability to achieve a gelatinization degree exceeding 95%. This high level of gelatinization is vital for increasing the digestibility of the feed, ultimately promoting better growth rates in fish and shrimp. The combination of uniform pellets and high gelatinization makes this food extruder a top choice for aquaculture operations.

Conclusion

In summary, the FAMSUN Twin-Screw Aqua Extruder is an essential asset for aquaculture businesses seeking to enhance feed quality. With its advanced technology and focus on uniformity, this food extruder ensures optimal performance, contributing to healthier aquatic species and more successful farming operations.